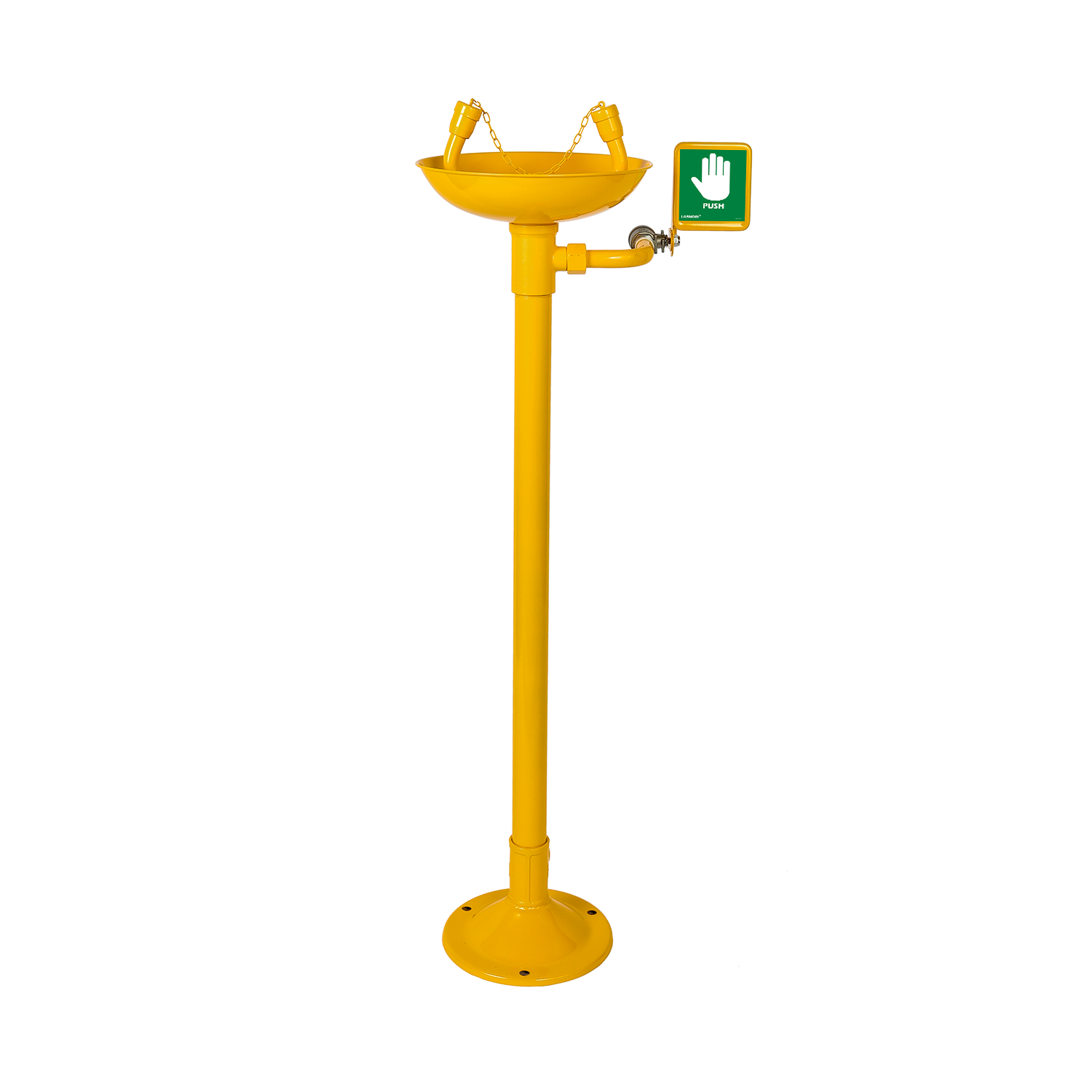

Application: Eye/face wash for pedestal mounting. Two spray heads deliver a flood of water over a wide area of coverage for complete rinsing of eyes and face.

Spray Head Assembly: Two spray heads. Each head has a dust cover, internal flow control and filter to remove impurities from the water flow.

Valve: 1/2" stainless stay-open ball valve with PTFE tape seals.

Bowl: 10-1/4" (260mm) diameter stainless steel.

Supply: 1/2" female inlet.

Waste: 1-1/4" female outlet.

Sign: Furnished with universal identification sign.

Quality Assurance: Unit is fully assembled and water tested prior to shipment. Unit is third-party certified to comply with ANSI Z358.1-2014.

Spray Head Assembly: Two spray heads. Each head has a dust cover, internal flow control and filter to remove impurities from the water flow.

Valve: 1/2" stainless stay-open ball valve with PTFE tape seals.

Bowl: 10-1/4" (260mm) diameter stainless steel.

Supply: 1/2" female inlet.

Waste: 1-1/4" female outlet.

Sign: Furnished with universal identification sign.

Quality Assurance: Unit is fully assembled and water tested prior to shipment. Unit is third-party certified to comply with ANSI Z358.1-2014.